The tanks and the external jacket are made by our company with rotational molding in 100% polyethylene.

The double-walled version increases safety and limits damage in the event of a spill, protecting the safety of operators and the environment.

Solid and long-lasting polyethylene tanks.

Solid and long-lasting polyethylene tanks.

-

Available in 14 days

-

All tanks are available in the double-wall version

-

Increases security

-

100% made in polyethylene, rotomoyulded without welding

-

Lightweight, very resistant and long-lasting

-

See the instructions for use

Resistant to most acids, bases and oils

100% recyclable

Easy to clean

Solid and resistant

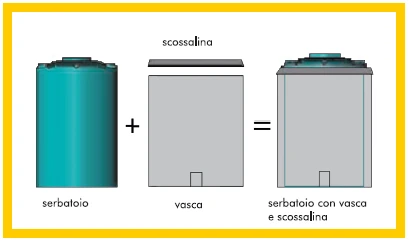

The external cistern (glass or jacket or double wall)

More and more often, for safety and prevention reasons, storage tanks are requested in the double-walled version, in which the tank is inserted into an external secondary containment tank.

This solution increases security.

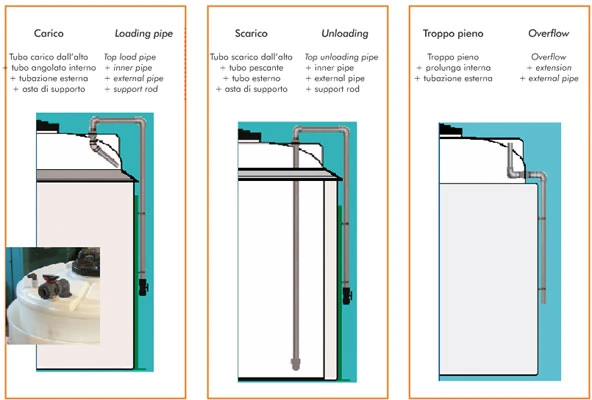

In this version both loading and unloading are carried out from above.

This solution increases security.

In this version both loading and unloading are carried out from above.